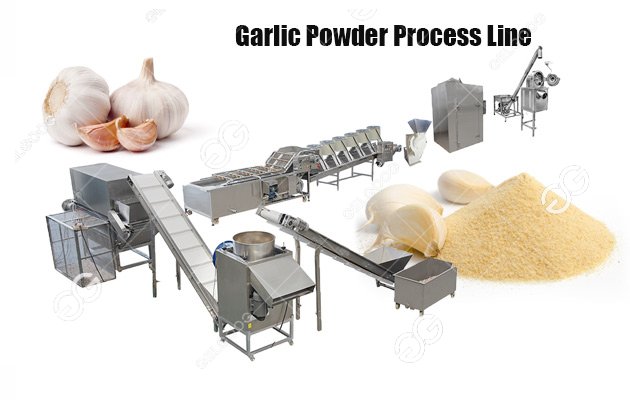

Garlic Process Machine Line|Garlic Powder Making Machine Line

Oct 26 2021

By Maria

Follow Us:

Oct 26 2021

By Maria

Follow Us:

①Materials: Choose fully mature, large, complete, mildew-free garlic as raw materials, remove the garlic stems with a knife, peel off the skin and the thin garlic flowers attached to the garlic cloves for use.

②Production: Wash the peeled garlic cloves with clean water, and remove the spots and discolored parts on the garlic cloves.

Use a slicer with water to cut into slices with a thickness of about 1.6 mm, and then rinse 3 to 5 times, and then centrifuge for about 2 minutes in a centrifuge for dehydration.

Spread the dehydrated garlic slices immediately, dry them, and spread them in a bamboo tray with a thickness of about 1.5 cm.

Dry them in a drying room at about 65°C. The garlic slices dried in this way are pale yellow.

The dried garlic slices are put into a pulverizer and crushed into powder, and passed through an 80-100 mesh sieve to obtain garlic powder. Pack garlic powder into 10-25g packets and sell it.

①Product features: light yellow color, no burnt black, no red flakes, and no fragments.

②Technical process: fresh garlic→cutting the stems→dividing, peeling the inner skin→slicing→rinsing→spinning water→sifting→drying→scaling clothes→sieving→selecting→packing.

③Making points:

Cut the stems and peel: Cut the qualified garlic heads to remove the garlic stems, pick out the garlic particles, peel off the underwear, and place them in a ventilated container in a dry, ventilated, and cool place. Strive for processing within 24 hours.

Slicing: Rinse with water to remove the dirt, rinse off the film, and then slice in a slicer with water, the slice thickness is about 1.5 mm, and slice while flushing.

Rinse: Put the cut garlic slices into a bamboo basket, and rinse with running water in a clear water tank to remove the mucus and sugar on the surface of the scales and the garlic slices. Generally, rinse 4 times.

De-water: Use a centrifuge to spin dry the surface of the garlic slices, about 2 minutes.

Drying: The sieving must be even and not too thick. After spreading and sieving, put the garlic slices in a drying room for drying. The temperature of the drying tunnel is about 65 ℃, and generally bake for 5 to 6 hours to reduce the moisture to 4% to 4.5%.

Packaging: Pack the selected garlic slices after inspection, and control the moisture content below 6% during packaging.