Ginger Juice Production Line Solution

Features

Introduction Of The Ginger Juice Production Line Solution :

This is the multi-function use ginger juice production line, the production process is simple, easy to operate. The ginger juice production strictly in accordance with international standards of manufacturing process, end products meet the requirements of food GMP health conditions . End products no need to be refrigerated transport and storage, product packaging form can be configured according to customer requirements.

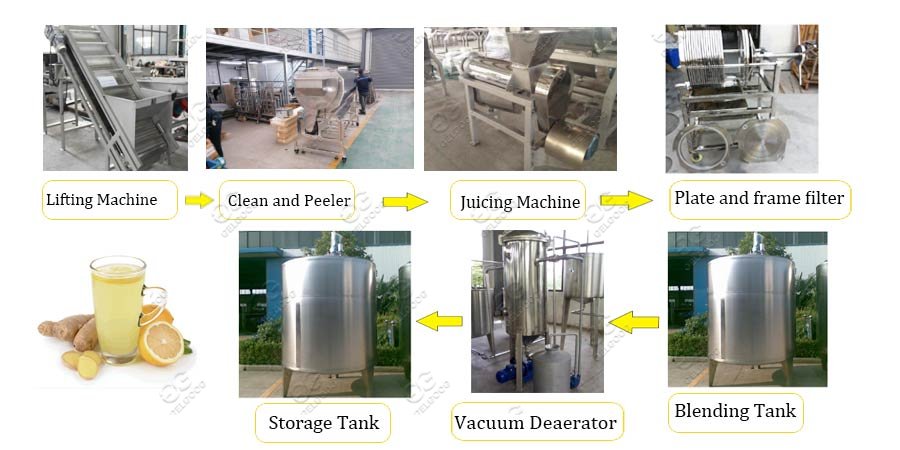

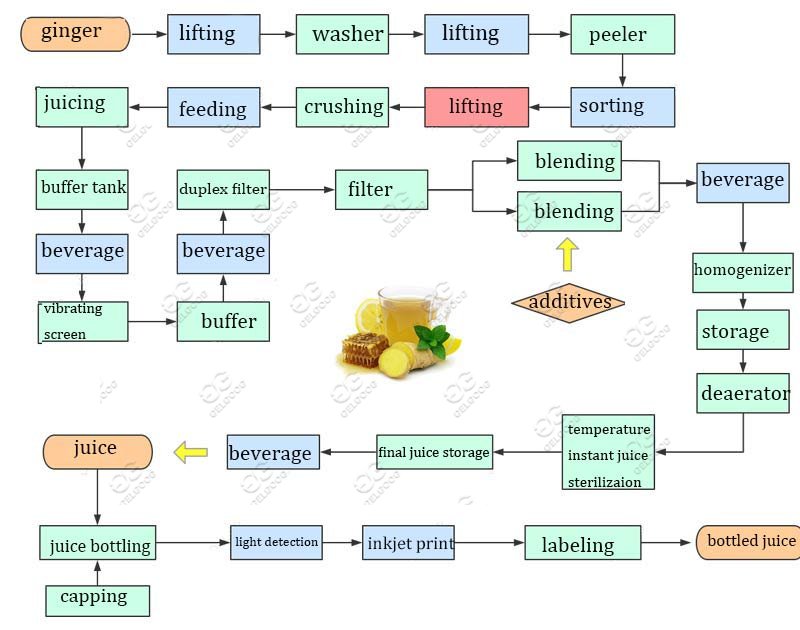

Ginger Juice Process Flow:

Ginger-Washing and peeling-Crushing-Juicing-Filtering-Concentrating-Mixing-UHT-Filling-Packaging.

1. Raw material processing:split the fresh ginger that needs to be processed, and wash away the soil and impurities with clean water;

2. Crushing: Use a crusher to crush the fresh ginger block into a coarse slurry. Because the ginger contains a lot of wood fiber, the selected crusher must have sharp crushing tools and screen holes;

3. Enzymatic treatment of fruit pulp; proper enzymatic treatment of fresh ginger fruit pulp can significantly increase the juice yield. Conditional production lines must have pulp heating and stirring devices;

4. Squeeze juice to extract juice; import the enzymatically hydrolyzed fruit pulp into Kaiyi KAAE belt juicer for juice extraction;

5. Pre-treatment of enzymatic hydrolysis; including pre-killing, adjusting PH value;

6. Enzymatic hydrolysis treatment; control the temperature of the reaction substrate at 50-55℃, add pectin decomposing enzyme, cellulase and other comprehensive enzyme preparations under uniform stirring, the action time is 50-60 minutes;

7. Centrifugal separation; the above-mentioned juice is further processed by a high-speed centrifuge to improve the purification effect of the juice liquid;

8. Ultrafiltration treatment: use a diatomaceous earth filter or ultrafiltration unit to further process the centrifuged ginger juice to obtain pure fresh ginger juice;

9. Concentrated processing; in order to facilitate storage, long-distance transportation, product export and meet the processing requirements of other products, the fresh ginger juice needs to be further concentrated and processed to make 36°Bx ginger concentrated juice, which is filled in aseptic bags or vats ;

Final Product

Application Scenario

Technical Data

| Machine Name | Machine Size(mm) | Power(Kw) |

| Bubble type washing machine | 2600×1000×1600 | 4.75 |

| Plate hoist | 3000×900×2000 | 0.75 |

| Hammer crusher | 1050×750×1800 | 4.00 |

| Forced feed pump | 1500×370×420 | 1.50 |

| Spiral fruit juicer | 1580×420×1400 | 4.00 |

| Temporary storage tank | Φ1000×600 | 0.00 |

| Juice pump | 400×300×350 | 0.75 |

| Preheater | 1500×460×1100 | 0.00 |

| Enzymatic hydrolysis tank | Φ1200×1900 | 1.50 |

| Juice pump | 400×300×350 | 0.75 |

| Plate and frame filter | 600×300×500 | 0.00 |

| Temporary storage tank | Φ1000×600 | 0.00 |

| Juice pump | 400×300×350 | 0.75 |

| Diatomaceous earth filter | 950×300×420 | 0.00 |

| Mixing tank | Φ1450×2300 | 2.20 |

| Juice pump | 400×300×350 | 0.75 |

| High pressure homogenizer | 1300×1100×1300 | 22 |

| Juice storage tank | Φ1450×2000 | 0 |

| Vacuum degasser | 1850×1000×2300 | 1.5 |

| Sterilizer machine | 2000×1200×2000 | 5 |

| Fruit juice finished can | Φ1450×2000 | 0 |