Mango Juice Process Line Solution

Features

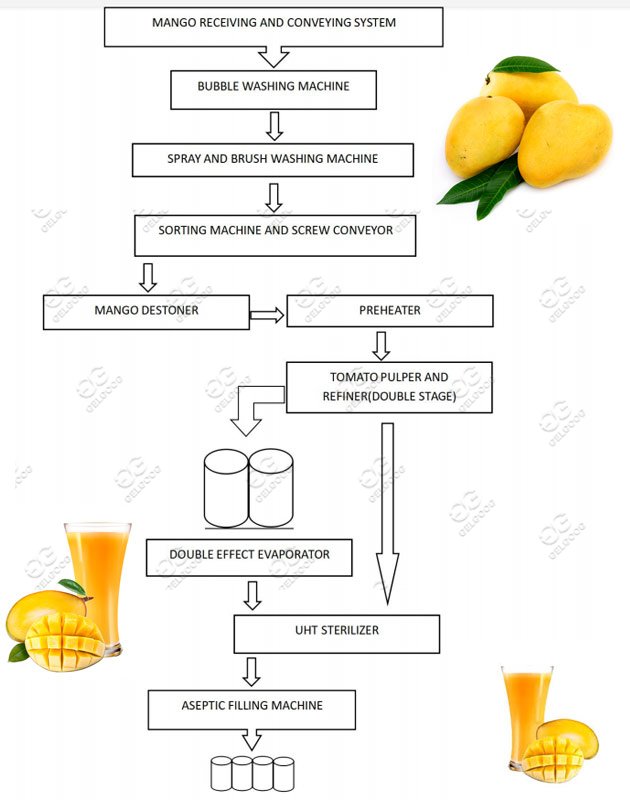

Flowchart for mango processing line

Main features of the mango juice making machine line:

1) All the machines are made of SUS 304, 316L optional.

2) Finally Packaging: usually, filled with aseptic bag in drum or aseptic bag in box. and then packed with small packaging. such as: plastic bottle, glass bottle, can, jar, tetra pack etc.

3) The line is also suitable for processing the fruits that share the similar characteristics.

4)Adopt 'hot-break' or 'cold-break' techniques to produce fruit paste which is different viscosity.

5) The production process fully automatic PLC control to save labor and faciliate production management.

6) Low-temperature vacuum evaporation, maximize reserve the flavor substances and nutrients, also save energy.

7) Tubular UHT Sterilizer and aseptic filling machine, produce high-quality fruit paste products.

Mango Pulp Making Machine :

Mango Pulp Making Machine :

Final Product

Application Scenario

Technical Data

| Machine Name | Machine Size(mm) | Power(Kw) |

| Bubble type washing machine | 2600×1000×1600 | 4.75 |

| Sorting machine | 3500×1000×1200 | 0.75 |

| Brush type cleaning machine | 2500×700×1100 | 0.75 |

| Plate hoist | 3000×900×2000 | 0.75 |

| Hammer crusher | 1050×750×1800 | 4.00 |

| Forced feed pump | 1500×370×420 | 1.50 |

| Spiral fruit juicer | 1580×420×1400 | 4.00 |

| Temporary storage tank | Φ1000×600 | 0.00 |

| Juice pump | 400×300×350 | 0.75 |

| Preheater | 1500×460×1100 | 0.00 |

| Enzymatic hydrolysis tank | Φ1200×1900 | 1.50 |

| Juice pump | 400×300×350 | 0.75 |

| Plate and frame filter | 600×300×500 | 0.00 |

| Temporary storage tank | Φ1000×600 | 0.00 |

| Juice pump | 400×300×350 | 0.75 |

| Diatomaceous earth filter | 950×300×420 | 0.00 |

| Mixing tank | Φ1450×2300 | 2.20 |

| Juice pump | 400×300×350 | 0.75 |

| High pressure homogenizer | 1300×1100×1300 | 22 |

| Juice storage tank | Φ1450×2000 | 0 |

| Vacuum degasser | 1850×1000×2300 | 1.5 |

| Sterilizer machine | 2000×1200×2000 | 5 |

| Fruit juice finished can | Φ1450×2000 | 0 |