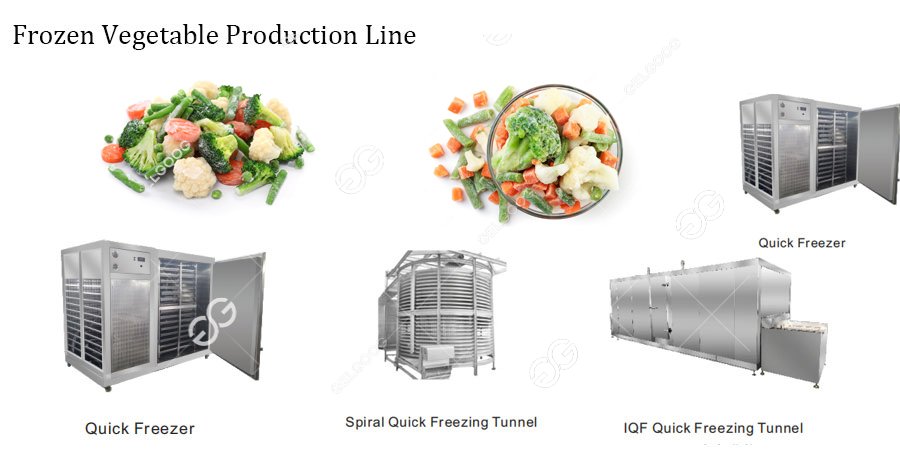

IQF Frozen Vegetable Production Line Solution

Features

Application of the IQF frozen vegetable production line

Gelgoog can provide a complete set of production line solutions for quick-freezing processing of granular, lumpy and other fruit and vegetable products. The pre-processing line is used for the washing and other processing of fruit and vegetable products before quick freezing are completed .

Process and equipment configuration of vegetable pretreatment production line:

Conveyor→drum type cleaning machine→Bubble type cleaning machine→ Blanching machine-→ Normal temperature water cooling machine → Ice water cooler→ Vibration dewater machine→air dryer→vibrating de-water machine→fluidized quick-freezing machine

1. Conveyor Machine :The main function is to make the material evenly distributed during the conveying process. The main structure is composed of a stainless steel conveyor belt and a motor reducer.

2. Drum type fruit vegetable washing machine:Mainly used to remove long filamentous debris such as hair, fiber, weeds, and vegetable roots. The main structure consists of rollers, motors, and transmission.

3. Bubble type fruit vegetable washing machine :It is mainly used for the preliminary cleaning of processed vegetables. Dirty vegetables, etc. enter the stainless steel sink and are carried by the stainless steel mesh belt.

4. blanching machine:The cleaned vegetables enter the blanching machine, and move forward in the water as the spiral plate rotates, In order to meet the different blanching times of different varieties of vegetables, frequency conversion speed regulation is used to adjust the spiral speed to meet the requirements

5. Normal temperature water cooler:The room temperature water cooler can quickly cool down the blanched vegetables, ensuring the color quality and taste of the vegetables

6. Vibration De-water Machine:Use high-frequency vibration to filter the water to reduce the water entering the single freezer and prevent the frozen products from sticking. The main structure of the vibrating water filter is made of stainless steel

7. vibration screening machine:It is used to distribute evenly to the fluidized quick-freezer. Mainly composed of frame, vibrating motor, screen body and other components.

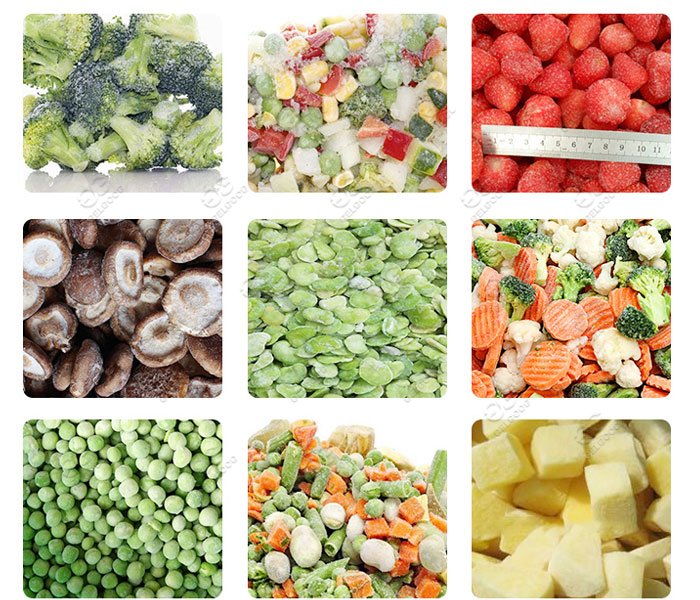

Final Product

Application Scenario

Technical Data

| Frozen Vegetables Production Line | ||||

| Machine name | Model | Machine Size | Power | Material |

| Washing Machine | GGXQ2500 | 2500x1100x900mm | Motor 0.75Kw fan 2.2Kw | 304 stainless steel |

| Picking Belt | GGDS3500A | 3500x700x900mm | Motor 0.37Kw |

PVC belt width 600mm |

| Vibration Drain | GGZTD1800 | 1800x1200x850mm | 0.5KW | 304 stainless steel |

| Vibrating feeding machine | GGZTD1800 | 1800x1200x1400mm | 0.5KW | 304 stainless steel |

| IQF Quick Freezer | GGIQF-100 | 5500x3400x2900mm | 20KW | 304 stainless steel |