Features

Garlic powder processing production line mainly includes: garlic breaking machine, peeling machine, slicer, dryer,powder grinding machine, packaging machine, etc.Each equipment is connected with each other by a hoist.

Introduction of garlic powder processing production line

1.Garlic breaking machine: The garlic breaking machine is the primary processing equipment of the whole garlic powder production line. It can be applied to both fresh garlic and garlic preserved in cold storage.

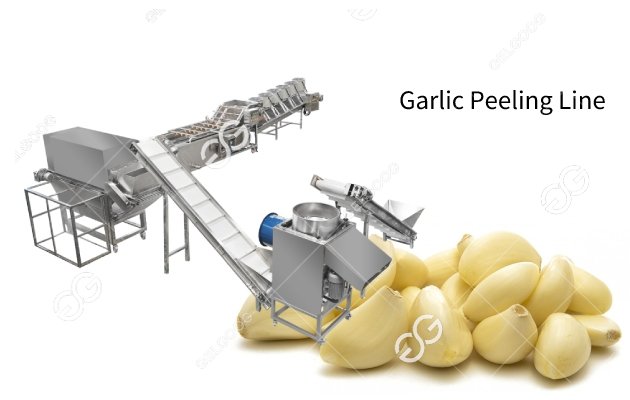

2.Garlic peeling machine:It is a cost-effective garlic peeling machine. The air peeling machine uses a pneumatic cycle peeling process. It is the equipment often used by many large garlic chip processing enterprises

3.Slicer: The garlic slices processed by the garlic slicer have standard product specifications with uniform thickness and size. This uniform garlic slice can keep the time and effect of the drying process under the same conditions, so the overall The drying effect will also be very high, which meets the processing standards of large-scale enterprises for drying garlic slices.

4.Dryer: Mesh belt type garlic slice dryer adopts multi-layer mobile stainless steel mesh belt, the drying process is hygienic and environmentally friendly, automatic temperature control, automatic material spreading, continuous production, high efficiency, and short drying cycle.

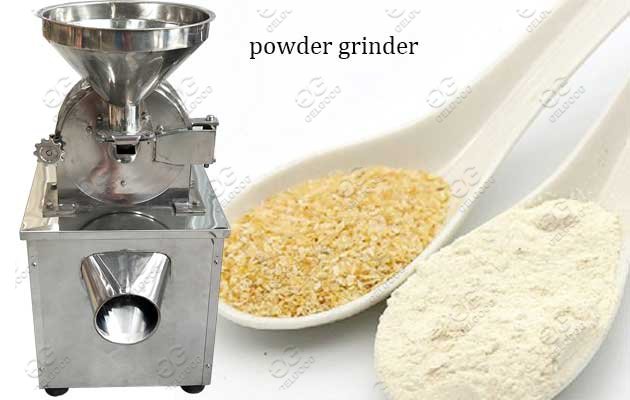

5. Grinding machine: Grind garlic slices into garlic powder, fineness can be controlled

6. Packaging: We can provide you with different packaging machines according to customers' packaging requirements

This garlic powder production line is mainly used for the separation and peeling of large quantities of garlic, it includes elevators, garlic bulb separators, picking lines, garlic peeling machines and finished product picking lines. Equipped with slicer, bubble cleaner, air dryer, dryer and other equipment, the garlic separation and peeling production line can be used for deep processing of garlic, such as dehydrated garlic flakes, garlic powder, garlic paste and other products. Adopting advanced technology, the output of garlic is high, and it is the most ideal equipment for garlic processing at present.

This garlic powder production line is mainly used for the separation and peeling of large quantities of garlic, it includes elevators, garlic bulb separators, picking lines, garlic peeling machines and finished product picking lines. Equipped with slicer, bubble cleaner, air dryer, dryer and other equipment, the garlic separation and peeling production line can be used for deep processing of garlic, such as dehydrated garlic flakes, garlic powder, garlic paste and other products. Adopting advanced technology, the output of garlic is high, and it is the most ideal equipment for garlic processing at present.

Technical Data

| Garlic Powder Process Production Line | |

| Garlic Separating Machine | Power:6.6kw |

| Voltage:380V50Hz3PH | |

| Dimension: 4000*1200*1400mm | |

| Elevator | Power:0.75kw |

| Voltage:380V50Hz3PH | |

| Dimension: 1800*800*1600mm | |

| Garlic Peeling Machine | Power:4.37kw |

| Voltage:380V50Hz3PH | |

| Dimension: 3100*900*1500mm | |

| Garlic Picking Belt | Power:0.75kw |

| Voltage:380V50Hz3PH | |

| Dimension: 3000*800*900mm | |

| Garlic Washing Machine | Power:3kw/380v |

| Voltage: 380V50Hz3PH | |

| Dimension: 4000*1000*1300mm | |

| Ginger Slicing Machine | Power;1.1kw |

| Voltage:220V50Hz1PH | |

| Dimension: 690*560*880mm | |

| Garlic Slice Drying Machine | Power:300kw |

| Voltage:380V50Hz3PH | |

| Dimension: 10000*2200*2000mm | |

| Elevator | Power:0.75kw |

| Voltage:380V50Hz3PH | |

| Dimension: 2000*1200*1400mm | |

| Garlic Powder Making Machine | Power:11kw |

| Voltage:380V50Hz3PH | |

| Dimension: 7000*1000*2400mm | |

| Garlic Power Packing Machine | Power:4kw |

| Voltage:380V50Hz3PH | |

| Dimension: 700*900*2100mm | |