Features

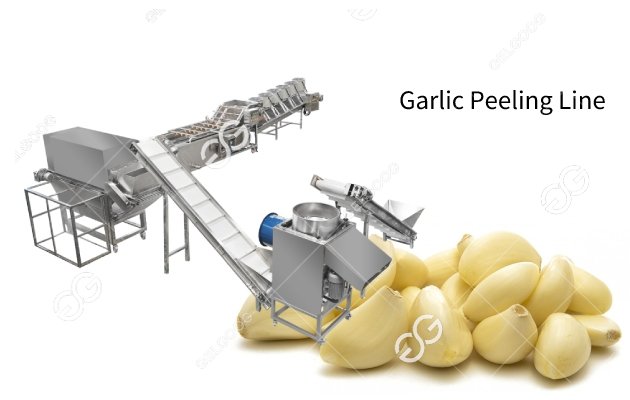

Garlic production line solution covers the entire process from breaking, peeling, cleaning to packaging. The solution has a compact structure, small footprint, large capacity and high work efficiency.

The equipment required for the garlic peeling processing production line mainly includes elevators, garlic breaking machine, garlic peelers, belt conveyors, bubble washing machine, air dryer, weighing packaging machines, etc.

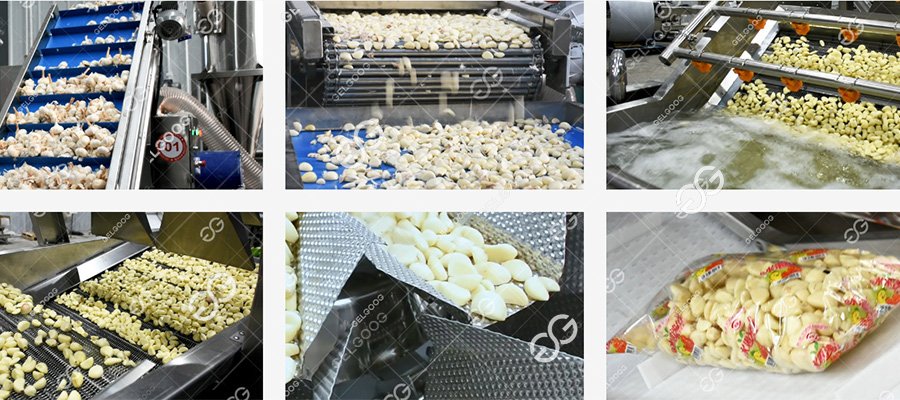

1.Garlic breaking machine : Garlic is divided into cloves, and the removed garlic skins are collected into the skin collection device, and the separated garlic cloves fall into the elevator and enter the peeling process.

2. Garlic peeling machine: The peeling rate of garlic is as high as 95%; the peeling rate of dry white garlic can even reach more than 99%. The garlic skins are collected into the skin collecting device, and the garlic is less damaged.

3. Picking belt: Peeled garlic enters the belt conveyor, and workers can sort out unpeeled garlic, garlic roots and other sundries.

4.Garlic washing machine: The picked garlic automatically enters the peeling washing machine, and the garlic is cleaned and sterilized

5. Air-drying: Use the strong wind of the air dryer to dry the surface moisture of the cleaned garlic, and remove the residual moisture of the garlic.

6. Weighing and packaging: Washed and air-dried garlic is packed into transparent plastic bottles or bags through a multi-head weighing packaging machine. After the garlic is peeled and processed, it can be sent to the market for sale through the cold chain.

The garlic peeling and processing production line designed by GELGOOG compnay produces garlic with a high peeling rate, less damage, and a high cleaning rate after cleaning and disinfection. After air-drying and packaging, the brand image is improved, and the shelf life of garlic is extended, which is convenient for storage and transportation.

Video:

Technical Data

| Machine Name | Dimension | Power/Material |

| Garlic Breaker Machine | 1600*900*1200mm | 3kw |

| 300-600kg/h | ||

| 304stainless Steel | ||

| PickingLine | 3500*800*800mm | 1.1kw |

| 304stainless Steel and Manual adjust Speed | ||

| Garlic Peeler | 2800*800*1650mm | 1.85kw |

| 304stainless Steel | ||

| Picking Line | 4000*800*800 mm | 1.1kw |

| 304stainless Steel and Manual adjust Speed | ||

| Air Bubble Washing Machine | 4000*1200*1400mm | 2.57kw |

| 304 Stainless Steel | ||

| Drying Machine | 4000*1100*1600mm | 2.78kw |

| 304stainless Steel | ||

| Sorter | 2.1m*0.6m*0.8m | 1.5KW |

| 304stainless Steel |