200kg/h Tomato Paste Making Machine Process Solution

Features

Tomatoes are usually processed into tomato paste and the processing line mainly includes :

It is mainly composed of discharge system, hydraulic convey system, bucket elevating, washing and sorting system, crushing system, pre-heating system, pulping and refining system, evaporating& concentrating system, sterilizing system, aseptic filling system. Tomato paste in aseptic drum can be further processed to ketchup, sauces, juices in tin can/bottle/pouch, etc.

Video About The Tomato Paste Making Machine Line :

Main Features Of The Tomato Paste Making Machine Line

1. The company's tomato sauce processing equipment design is reasonable, beautiful, stable operation, high efficiency and energy saving, low steam consumption.

2. Concentration system adopts forced circulation vacuum concentrating evaporator, which is used for concentrating high viscosity materials such as jam, fruit pulp, syrup and so on. It makes the viscosity of tomato paste easy to flow and evaporate, and the concentration time is short. And according to customer requirements, tomato sauce from 4.5-5.5% Brix concentrated to 28-30%, Brix, 30-32%, Brix, 36-38% Brix,

3. The evaporating temperature is low, the heat has been fully utilized, tomato sauce heating moderate, in the tube heating evenly.

4. The use of a special structure of the condenser, the cooling water temperature of 30 degrees, or even higher, the normal operation.

5. Continuous feeding and unloading, liquid level and concentration required to achieve automatic control.

Gelgoog Also Provide:

Tomato Sauce Making Machine Line

Ketchup Production Line

Tomato Puree Process Machine Line

Gelgoog Also Provide:

Tomato Sauce Making Machine Line

Ketchup Production Line

Tomato Puree Process Machine Line

Final Product

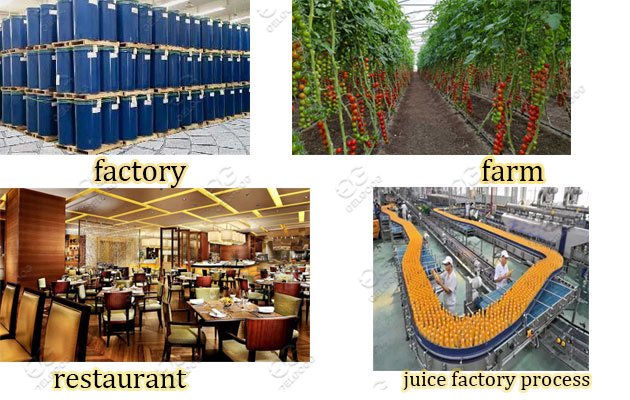

Application Scenario

Technical Data

| Tomato Paste Production Line Main Machine | Main Parameters |

| Hoist |

Hoist power: 0.75kw Size: 2000 * 800 * 1600mm |

| Bubble type tomato washing machne |

Powder:4.45KW / 380V / 50Hz Size: 2500x1200x1300mm |

| Impurity removal machine |

Size: 3000 * 1000 * 1400 Power: 5.2KW |

| Broken screw pump |

capacity: 0.5-1 ton / hour; Power: 1.5KW; Dimensions: 1500 × 500 × 500mm; |

| Enzyme inactivation equipment |

capacity: 1T / H Size: 1220 × 615 × 1250mm |

| Pulp machine |

capacity: 1-2.5 tons / hour Power: 380V, 50Hz, 4Kw; |

| Temporary storage tank |

storage tank: 500L; Exit: φ25.4mm clamp quick-install interface; Tank body: φ500 × 800 × δ = 2mm; Discharging height: 200mm, φ25.4mm quick-install interface; Dimensions: 500 × 1200mm; |

|

sandwich pans Stirring |

power: 1.5KW Heating power: 24KW If the burner is configured: 10W Kcal Dimensions: 1100 * 980 * 1600 Body size: 800 * 550 |

|

Filling machine |

1200 * 350 * 350 Voltage 200-250V Frequency 50 or 60HZ |