Features

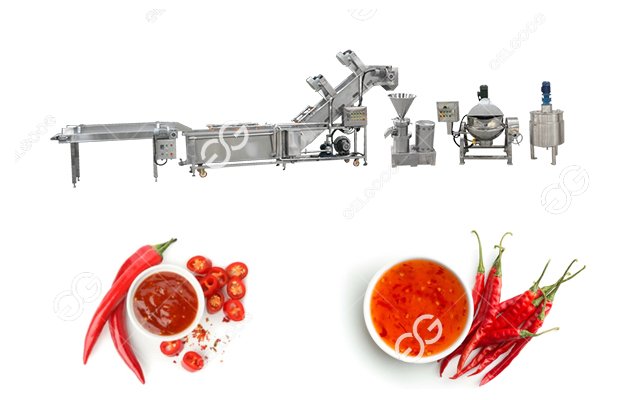

Small Scale tomato ketchup making machine line

This small ketchup production line can directly produce ketchup, saving cost and manpower:Raw material → washing → crushing → heating and concentration → sterilization → filling → sterilization.

1.Grading of raw materials: Choose fully mature fruits with bright color, high dry matter content, thin skin, thick flesh, and few seeds as raw materials.

2.Cleaning: Wash the silt and dirt on the fruit surface with clean water.

3.Crushing: Pour the tomatoes into the beater, break the pulp, and remove the skin seeds. The beating machine is preferably a double-pass beating machine.

4.Heating and concentration: Put the juice in a jacketed pot and heat and concentrate

5.Tomato ketchup sterilization:The concentrated tomato ketchup is homogenized and sterilized through a jacketed pot. The ketchup is more even and delicate.

6.Filling :Packaging type and weight are optional, bottled or bagged.

7.Sterilization: Sterilize in boiling water for 20-30 minutes

5.Tomato ketchup sterilization:The concentrated tomato ketchup is homogenized and sterilized through a jacketed pot. The ketchup is more even and delicate.

6.Filling :Packaging type and weight are optional, bottled or bagged.

7.Sterilization: Sterilize in boiling water for 20-30 minutes

The main equipment includes: washing machine, beater, jacketed pot and filling machine, sterilization machine and other equipment.

The main features of the tomato ketchup production line:

1. The complete system has reasonable and beautiful design, stable operation, energy saving, and low steam consumption.

2. All contact materials are made of stainless steel, which is in full compliance with GMP standards;

3. Fast live connection, simple and quick disassembly and washing;

4. The filling volume and filling speed are easily adjustable, and the bottles of different specifications and shapes can be replaced without replacing parts, and the adjustment is easy;

5. The filling head is equipped with a leak-proof device, and there is no drawing dripping when filling.

Technical Data

| Description | Technical specifications |

|

Bubble washing and drying machine |

◎Capacity:0.3-0.5t/h; ◎Power:3.7kw/380v/50hz/3p ◎Dimension:4000*1000*2450mm; ◎Water recycling system; ◎Elevator:PU Material |

| Crusher machine |

◎Capacity:0.3-0.5t/h; ◎Power: 2.2kw/380v/50hz/3p; ◎Dimension:630*550*1455mm; |

| Heating and concentration/sterilization |

◎Capacity:200liters; ◎Power:1.1kw+18kw/380v/50hz/3p; ◎Dimension:1100*980*1600mm; ◎Pot body size:800*550mm |

|

Sachet packing machine |

◎Model:LY300C; ◎Power:1.8Kw/220v/50hz/1p;; ◎Dimension:920*720*1800mm; ◎Weight: 400kg; ◎Bag size: Length: 40-150mm, Width: 20-130mm. ◎Packing Range: 10-100grams. ◎Packing Speed: 40-80 bags/min |

|

Sterilizer machine |

◎Power:24kw/380V/50Hz/3phase; ◎Dimension:1200*700*950mm; ◎Weight:100kg. ◎The basket size:500*500*240mm*2. ◎The bottle will be sterilized in the hot water between 60-80℃. |