Features

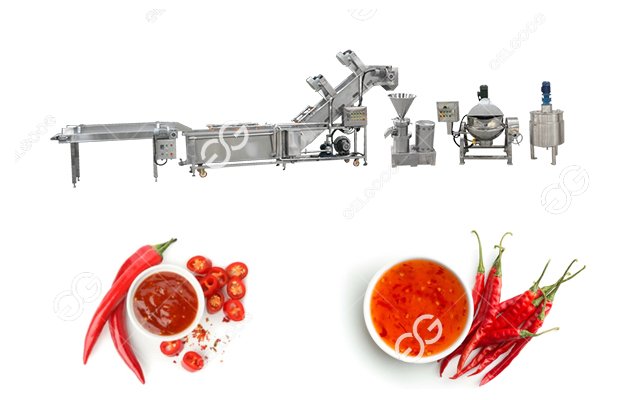

Tomato Paste Making Machine Plant

The tomato paste making machine plant can also process blackberry sauce, strawberry sauce, blueberry sauce, apple sauce, mango sauce, apricot sauce, carrot sauce, onion sauce, chili sauce and many other fruit jams.

The tomato paste making machine plant can also process blackberry sauce, strawberry sauce, blueberry sauce, apple sauce, mango sauce, apricot sauce, carrot sauce, onion sauce, chili sauce and many other fruit jams.

Advantage of Tomato Paste Making Machine Plant :

1.High output:we have the capacity of 300kg/h,500kg/h,1000kg/h,etc.

2.Save resources :Advanced product design and technology, stable and reliable,can increase labor productivity, stably improve product quality, and improve labor Conditions, reduce production area, reduce production costs, shorten production cycles,Ensure production balance and significant economic benefits.

3.Simple operation It works smoothly, with low noise and long service life.

4.The tomato sauce production line uses food-grade stainless steel parts and materials, which is strong and durable.

5.Meet the different needs of customers, with good output, good effect and saving time.

Tomato processing lines can produce tomatoes from fresh tomatoes to various products. The popular one is the tomato paste production line, from fresh tomato to the production of tomato paste in barrels with aseptic bags. It mainly includes: fresh tomato receiving system, cleaning system, sorting system, extraction system, concentration system, disinfection system and aseptic filling system. Then put the tomato paste with a sterile bag into the bucket. The ketchup packed in aseptic bags in barrels can be further made into ketchup, sauce, juice, and then packed into stand-up pouches, metal cans, PP containers, bottles, etc. If you need, we can also provide a separate tomato paste grinder

Tomato processing lines can produce tomatoes from fresh tomatoes to various products. The popular one is the tomato paste production line, from fresh tomato to the production of tomato paste in barrels with aseptic bags. It mainly includes: fresh tomato receiving system, cleaning system, sorting system, extraction system, concentration system, disinfection system and aseptic filling system. Then put the tomato paste with a sterile bag into the bucket. The ketchup packed in aseptic bags in barrels can be further made into ketchup, sauce, juice, and then packed into stand-up pouches, metal cans, PP containers, bottles, etc. If you need, we can also provide a separate tomato paste grinder

Technical Data

| Description | Technical specifications |

|

Bubble washing and drying machine |

◎Capacity:0.3-0.5t/h; ◎Power:3.7kw/380v/50hz/3p ◎Dimension:4000*1000*2450mm; ◎Water recycling system; ◎Elevator:PU Material |

| Crusher machine |

◎Capacity:0.3-0.5t/h; ◎Power: 2.2kw/380v/50hz/3p; ◎Dimension:630*550*1455mm; |

| Heating and concentration/sterilization |

◎Capacity:200liters; ◎Power:1.1kw+18kw/380v/50hz/3p; ◎Dimension:1100*980*1600mm; ◎Pot body size:800*550mm |

|

Sachet packing machine |

◎Power:1.8Kw/220v/50hz/1p;; ◎Dimension:920*720*1800mm; ◎Weight: 400kg; ◎Bag size: Length: 40-150mm, Width: 20-130mm. ◎Packing Speed: 40-80 bags/min |

|

Sterilizer machine |

◎Power:24kw/380V/50Hz/3phase; ◎Dimension:1200*700*950mm; ◎Weight:100kg. ◎The basket size:500*500*240mm*2. ◎The bottle will be sterilized in the hot water between 60-80℃. |