Advantages Of Tomato Paste Production Line Solution

Jun 14 2022

By Maria

Follow Us:

Jun 14 2022

By Maria

Follow Us:

When you eat french fries, what is missing that doesn't taste good? When you eat chicken nuggets, what tastes more delicious with dipping? When you bake something with diced onions, it instantly wafts off the fast-food burger smell? The answer is ketchup! Tomato sauce is delicious and complicated to make.

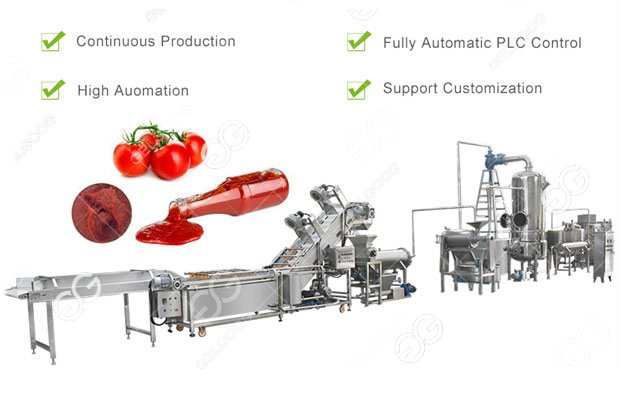

First,we need to product tomato paste .Tomato paste processing equipment solutions include tomato lifting system, cleaning system, sorting system, crushing system, preheating and inactivating enzyme system, beating system, vacuum concentration system, sterilization system, aseptic big bag filling system.

Features of tomato paste production line :

1. The tomato paste production line equipment fully considers that the investor can obtain the best production capacity and economic benefits with the smallest equipment investment, greatly save the equipment investment, and maximize the input-output ratio;

2. Considering the actual situation of the customer's factory and the equipment requirements of the project, the installation and positioning of the tomato paste production line equipment adopts segmented positioning, which ensures the rationality of on-site construction and operation, as well as a good on-site working environment;

3. The tomato paste production line equipment adopts a low-temperature vacuum evaporator, which greatly reduces the energy consumption; at the same time, the low-temperature state retains the flavor and nutrients of the tomato to the greatest extent. For the cooling water of the evaporator, the external reservoir is used for circulating supply to reduce the waste of cooling water;

4. The entire process design and pipeline connection layout take into account the retention of the original natural aromatic components of the tomato paste product. The entire cooling and heating process and material transmission are completed in a short time and a short distance, effectively preventing the flavor substances produced by thermal reactions. At the same time, it also reduces the quality damage caused by the oxidation reaction of tomato puree at high temperature.

Advantages of tomato paste production line ;

1. The material contact parts of the system are all made of 304 stainless steel, and the ketchup processing equipment fully meets the requirements of food hygiene and safety;

2. The whole production process is controlled by PLC, and the electrical components are all well-known brands, which saves labor and improves the level of automation;

3. The double-channel beater is used to improve the juice extraction efficiency and juice yield, and increase the output;

4. Low temperature vacuum concentration, the flavor substances and nutrients are fully retained, and the energy is greatly saved;

5. Strong compatibility, can handle fruits with similar characteristics;

6. It occupies a small area and is not very restrictive to the processing site.

GELGOOG Machinery has continuously improved the design concept and process technology of the tomato paste production line, and has achieved a complete set of turnkey projects such as the design, manufacture, installation and commissioning, and training of the tomato paste production line processing scheme. The tomato paste production line can process concentrated fruit and vegetable products such as strawberry jam, blackberry jam, blueberry jam, raspberry jam, apple jam, mango jam, apricot jam, carrot jam, onion jam, chili jam, etc.