Features

Yam Chips Process Machine Line|Cassava Chips Making Machine Line

Yam chips and cassva chips is a very popular snack.This yam and cassava chips process machine line is made of 304 stainless steel, which provides the most reasonable cassava chip production process and the whole set of formula and technical guidance. It is the first choice for food process companies to carry out yam and cassava deep processing.

Yam chips and cassva chips is a very popular snack.This yam and cassava chips process machine line is made of 304 stainless steel, which provides the most reasonable cassava chip production process and the whole set of formula and technical guidance. It is the first choice for food process companies to carry out yam and cassava deep processing.

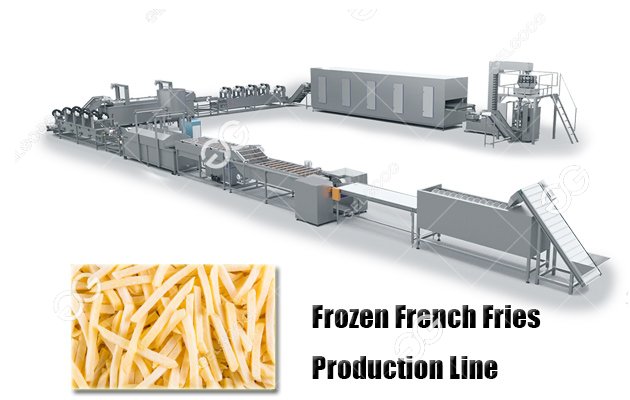

Process Procedures of Cassava Chips Making Machine

Cassava washing and peeling----strip cutting----blanching---dewater---frying----deoiling---flavoring---packing

1. Washing and peeling machine: The brush type cleaning and peeling machine can complete the cleaning and peeling work at the same time. High efficiency and low loss.

2. Rinse cutting strips (slices): the cutting strip size can be adjusted from 6mm to 10mm.

3. Blanching machine: rinse and protect the cut cassava chips (french fries ).

4. Dewater machine: dewatering by centrifugal force. Dehydration before frying can greatly shorten the frying time and improve the taste of cassava chips (french fries).

5. Frying:The resulting residue is directly deposited in the water, which greatly prolongs the service life of the oil and reduces the cost. The oil temperature is precisely controlled, thus ensuring the quality and taste of potato chips and fries.

6. De-oiling machine: Vibrating the de-oiling machine to de-oil the freshly fried cassava chips (french fries), overcoming the defects of high oil content and greasy mouth of the cassava chips (french fries). Improves the taste of chips (fries).

7. Seasoning machine: The cassava chips (french fries) after deoiling are used for seasoning and mixing. The structure is simple and practical. Disinfection is convenient and no dead ends.

Feature Of The Cassava Chips Process Machine Line

1.Low cost,low energy-exhausting,multifunction, small dimension,high profit, and easy-repairing are its best features.

2.It is composed of Washing & Peeling Machine, potato chips machine, Blanching machine, dewatering machine, frying machine, deoiling machine,packing machine.

Technical Data

| Machine Name | Power(kw) | Voltage | Weight(kg) | Dimension(mm) | Capacity(kg/h) |

| Yam Washing Peeling Machine | 0.75 | 380V-3/220V-3 | 90 | 650*550*800 | 200 |

| Yam Cutter | 4.75 | 380V-3/220V-3 | 110 | 950*900*1000 | 600 |

| Blanching Machine | 9 | 380V-3/220V-3 | 80 | 700*700*900 | 60 |

| Dewater Machine | 1.5 | 380V-3/220V-3 | 300 | 900*500*800 | 200 |

| Fryer | 12 | 380V-3/220V-3 | 80 | 700*700*900 | 20 |

| De-oiling Machine | 1.1 | 380V-3/220V-3 | 300 | 900*500*800 | 200 |

| Flavoring Machine | 1.1 | 380V-3/220V-3 | 150 | 1100*800*1300 | 200 |

| Vacuum Packing Machine | 1.1 | 380V-3/220V-3 | 80 | 500*500*800 |

20 |