Features

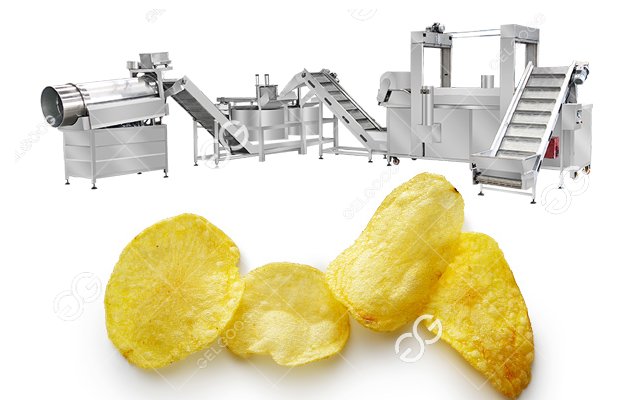

Potato Chips Production Line

Our potato chip production line uses fresh potatoes as raw materials. It can produce crispy and high-quality potato chips. We use the latest and most advanced technology to design these potato chip machines. The processing flow of potato chip making machine:

Potatoes→cleaning and peeling→selection→Slice

cleaning→Blanching→drying

frying→deoiling→seasoning→Packing

Our potato chip production line uses fresh potatoes as raw materials. It can produce crispy and high-quality potato chips. We use the latest and most advanced technology to design these potato chip machines. The processing flow of potato chip making machine:

Potatoes→cleaning and peeling→selection→Slice

cleaning→Blanching→drying

frying→deoiling→seasoning→Packing

Main Machine Of The Potato Chips Production Line :

1. Washing and peeling machine: Brush type washing and peeling machine can wash and peel potatoes.

2. Slection machine: get rid of rotten potatoes.

3. Cutting machine: cut into slice, the cutting size is adjustable.

4. Washing machine: remove starch from potato chips.

5. Blanching machine: Rinse the cut potato slices and protect the color

6. De-water and air-cooling machine: air-dried potato chips,remove water from potato chips.

7. Fryer: Frying potato chips.

8. De-oil Machine machine: remove the oil on potato chips.

9. Seasoning machine: Add spices to potatoes.

10.Packing Machine:we also can offer the packing machine to pack potato chips in bags .

10.Packing Machine:we also can offer the packing machine to pack potato chips in bags .

The whole automatic potato chip production line is made of imported stainless steel material, which is exquisite in workmanship and durable. It adopts intelligent digital display thermostat, which is convenient and practical. It is equipped with an over-temperature protection device, so you can use it with confidence. It is a smokeless, multi-functional, water-oil mixed frying equipment. This equipment adopts the international oil-water mixed frying process, which has changed the traditional frying equipment. The structure fundamentally solves the disadvantages of the traditional deep fryer. It can fry all kinds of food at the same time without smelling each other, and it can be used for multiple purposes. The fried food is not only good in color, aroma and taste, but also has a clean and beautiful appearance, and improves the Product quality, extended shelf life.

Technical Data

| Item Name | Power(kw) | Voltage | Dimension(mm) |

| Elevator | 0.75 | 380v/50HZ | 2000*800*2000 |

| Washing and Peeling Machine | 4.75 | 380v/50HZ | 2600*900*1500 |

| Sorting Conveyor Line | 0.75 | 380v/50HZ | 3000*900*900 |

| Potato Chips Cutter Machine | 1.5 | 380v/50HZ | 950*800*950 |

| Rinsing Machine | 5.5 | 380v/50HZ | 4000*1600*900 |

| Blanching Machine | 125 | 380v/50HZ | 4000*1600*950 |

| Air Dewatering Machine | 7.1 | 380v/50HZ | 4000x1200x1400 |

| Sorting Conveyor Line | 0.75 | 380v/50HZ | 3000*800*950 |

| Elevator | 0.75 | 380v/50HZ | 2500*800*1300 |

| Frying Machine | 123 | 380v/50HZ | 4500x1200x2600 |

| Vibrating Type Oil Removing Machine | 1.5 | 380v/50HZ | 1500x1000x1300 |

| Air Drying Machine | 7.1 | 380v/50HZ | 4000x1200x1600 |

| Elevator | 0.75 | 380v/50HZ | 2400x800x2200 |

| Flavoring Machine | 0.75 | 380v/50HZ |

2600*1000*1600 |