Features

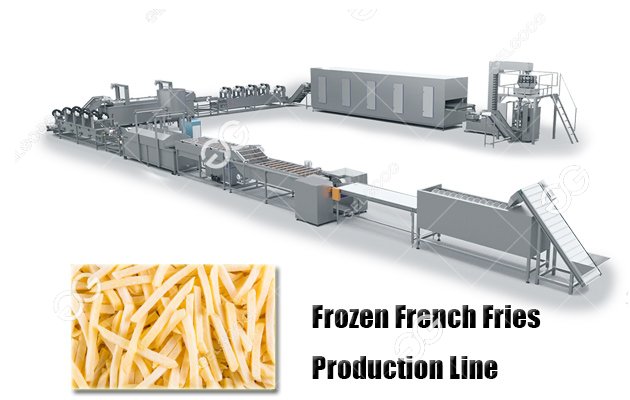

Gelgoog offer the small scale french fries making machine line.Suitable for small and medium food processing factory.This french fries line is lower in price and high efficiency, and it is your best choice for processing potato french fries.

How to make french fries step by step?

Potato washing & peeling - french fries cutting - french fries blanching - french fries dewatering - French fries frying -french fries de-oiling - French fries .if you need , we also can offer the flavoring machine and french fries packing machine .

Main Feature Of The Small Scale French Fries Making Machine Line

1.Raw materials:fresh potatoes,also can be used for other root vegetables,such as sweet potatoes,purple sweet potato,taro,cassava,etc

2.Final products:fried chips(flat and wave shape),french fries,also can be adjusted to produce frozen french fries,with packing machine to pack into bags

3.The whole line is made of stainless steel,healthy and easy to clean;Very reasonable price for the equipment.

4. This french fries production line is easy to install, just need to put the machines in the specially sequence as the working flowchart shows and connect the power of each machine, and then you can operate the machines to do normal production.

5.To operate this french fries processing production line needs 2-3 people, it maybe different according to your actual situation and your own arrangement.

Technical Data

| Item Name | Power(kw) | Voltage | Weight(kg) | Dimension(mm) | Capacity(kg/h) |

| Potato Washing Peeling Machine | 0.75 | 380V-3/220V-3 | 90 | 650*550*800 | 200 |

| Potato Cutter | 4.75 | 380V-3/220V-3 | 110 | 950*900*1000 | 600 |

| Blanching Machine | 9 | 380V-3/220V-3 | 80 | 700*700*900 | 60 |

| Dewater Machine | 1.5 | 380V-3/220V-3 | 300 | 900*500*800 | 200 |

| Fryer | 12 | 380V-3/220V-3 | 80 | 700*700*900 | 20 |

| De-oiling Machine | 1.1 | 380V-3/220V-3 | 300 | 900*500*800 | 200 |

| Flavoring Machine | 1.1 | 380V-3/220V-3 | 150 | 1100*800*1300 | 200 |

| Vacuum Packing Machine | 1.1 | 380V-3/220V-3 | 80 | 500*500*800 |

20 |