Features

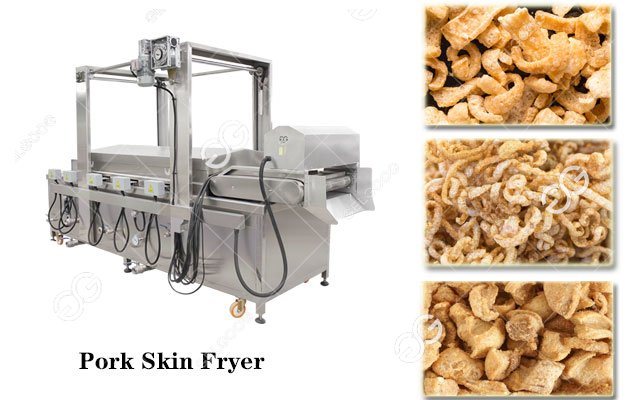

The pork skin frying machine can choose electric heating, gas heating, external heating and other methods. It is a smokeless, multi-functional, oil-water mixed frying equipment. The structure of traditional frying equipment solves the drawbacks of traditional frying pans. It can fry various foods at the same time without smelling each other. One pork skin frying machine is multi-purpose. This process adopts the method of heating from the middle of the oil layer to control the temperature of the upper and lower oil layers, which is effective Relieve the oxidation degree of frying oil, inhibit the rise of acid medium, automatically filter residual inspection during frying process, and automatically control temperature, thereby prolonging the service life of frying oil. The pork skin frying line is all conveyed by mesh belts. The mesh belt can adjust the speed at will according to the customer's own needs

The automatic pork skin frying machine is mainly suitable for larger food production enterprises, and the applicable products are: broad beans, green beans, peanuts and other nuts; puffed food such as rice noodles and potato chips; Noodle products; meat products such as meat pieces and chicken legs; aquatic products such as yellow croaker and hairtail; bean products such as dried bean curd and bean curd foam, etc.

Features of the pork skin frying equipment:

1. Automatic filtration: The oil-water separation frying process is designed, and the residues generated during the frying process of the food are automatically filtered into the water, which ensures the cleanliness of the oil body, improves the quality of the product, and brings higher quality to the product. while increasing the service life of the grease;

2. High heat utilization rate: CFD dynamic simulation design of heat exchanger, multi-layer pipeline distribution design, hot air flow in the heat exchanger to form an "S"-shaped flow direction, increase the residence time of heat in the pipeline, reduce energy loss, heat The utilization rate is greatly improved compared with traditional equipment;

3. Independent temperature control system for water layer: dual cooling measures of natural wind and forced water circulation are adopted at the bottom of the heat exchanger to ensure that the water temperature of the lower layer is kept below 55°, ensuring the safety of the oil-water contact layer;

4. Even frying: The upper and lower double-layer mesh belts are designed to keep the frying color of the product evenly when the product floats during the frying process, and the phenomenon of uneven frying of the floating food will not occur;

5. Automatic temperature control: The oil temperature is automatically controlled throughout the whole process, and the temperature can be set at will from 0-230 degrees, which is suitable for frying foods with different technological requirements;

6.After the mesh belt is separated from the equipment, it is easy to clean, which ensures the hygiene of food production and is safe and reliable;

7. Wide range of application: advanced mechanical transmission and frequency conversion speed control system, making the equipment suitable for frying all kinds of food;

Technical Data

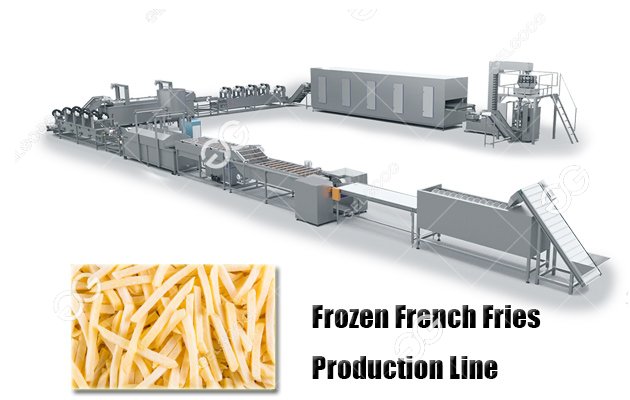

| Model | Heating Method | Power(KW) | Size(mm) | Capacity(before frying) |

| LZE2000 | Electric | 54 | 2200*785*1350 | French fries 190kg/h |

| Potato chips 60kg/h | ||||

| LZE3500 | Electric | 90 | 3700*1600*2200 | French fries 330kg/h |

| Potato chips180kg/h | ||||

| LZE5000 | Electric | 144-171 | 5200*1600*2200 | French fries 400kg/h |

| Potato chips220kg/h | ||||

| LZG2000 | Gas | 10W C | 2200*800*1400 | French fries 190kg/h |

| Potato chips60kg/h | ||||

| LZG3500 | Gas | 20W C | 3700*1900*2400 | French fries 380kg/h |

| Potato chips120kg/h | ||||

| LZG5000 | Gas | 30W C | 5200*1900*2400 | French fries 570kg/h |

| Potato chips180kg/h |