Features

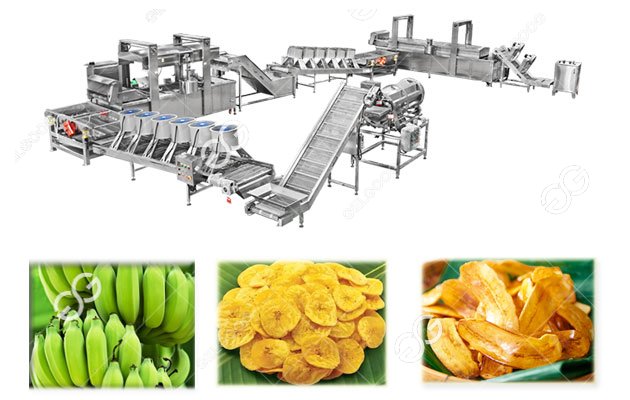

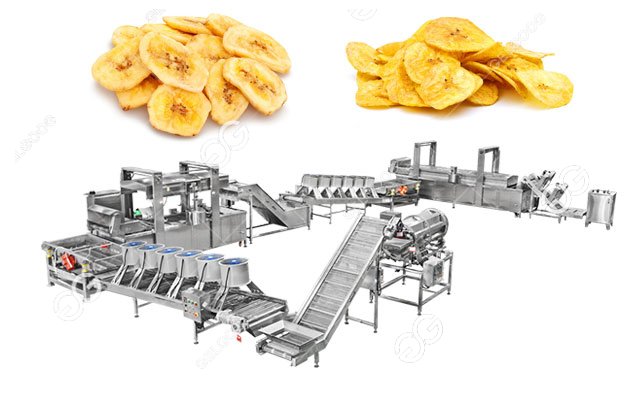

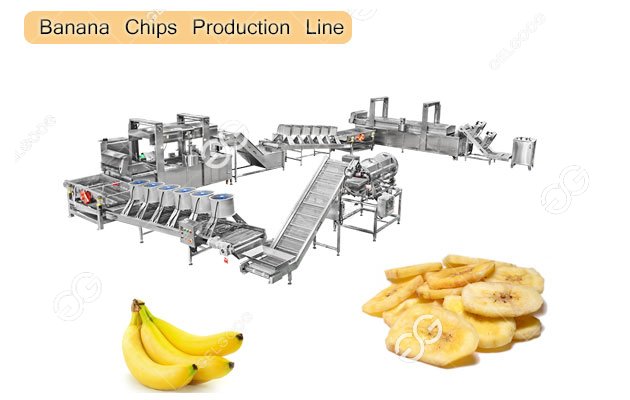

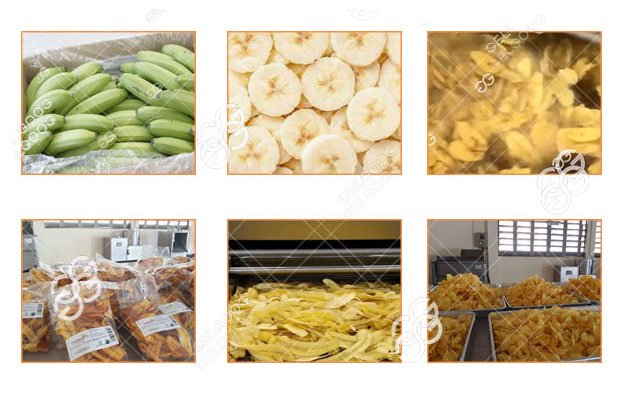

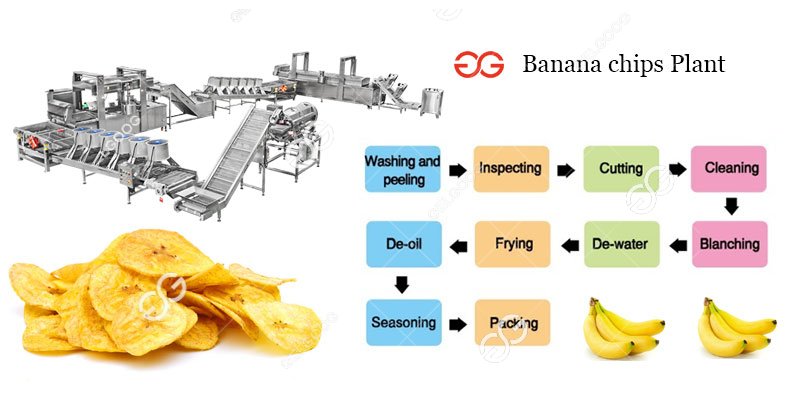

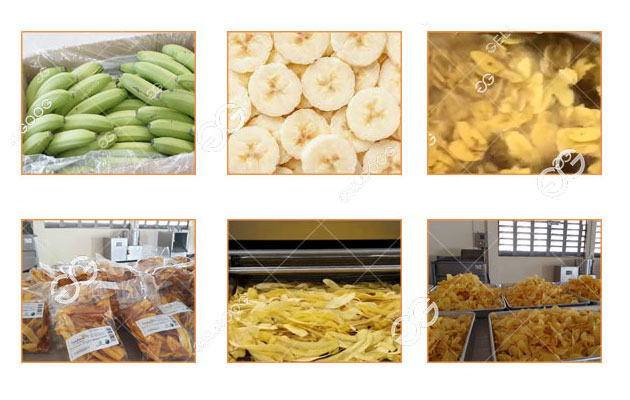

The Banana Chip Making line|Plantain Chips Production Line is used to make plantain chips or banana chips. Mainly include banana chip cutting machine, banana frying machine, banana icing machine, banana chip seasoning machine, banana chip packaging machine. We can cut bananas into different shapes to get different banana slices, such as round banana slices, long banana slices or diagonal banana slices.

Processing technology

Machine introduction of the banana chips production line :

1. Slicing machine: The slicing machine is designed according to the design plan of foreign companies. The equipment slices evenly and the output is high, about 1.5 tons per hour.

2. Blanching machine: Rinse and protect the color of the cut banana/plantain chips (strips).

3. Dehydration machine: using assembly line air drying dehydration, dehydration before frying can greatly shorten the frying time and improve the taste. Improve production efficiency and reduce production costs.

4. Frying machine: This equipment is a more advanced frying equipment developed by our company. The heating method can be electric heating, gas-fired coal heating, etc. The heating method is customized according to the needs of customers.

5. De-oiling machine: The air-drying de-oiling machine can de-oil the freshly fried banana slices, which overcomes the defects of high oil content and greasy taste of banana slices. Improve the taste of banana chips.

6. Automatic seasoning machine: The drum-type seasoning machine is made of stainless steel. The potato chips (strips) are turned evenly in the rotation of the drum, and seasonings are added by sprinkling or spraying. The seasoning is even and not fragile.

7. Nitrogen-filled packaging machine: When packaging, fill the packaging bag with nitrogen, which can effectively prevent the banana slices from breaking and prolong the shelf life. Inflation, packaging, and coding can be completed at one time.

Video

Precautions of the banana chips machine :

1.Blanching: temperature 80-90C, time 2-3min;The main function of blanching is to protect the color;

2.The first frying: temperature 160-180°C, time 3min;

3.Sugar dip: 30-40% sucrose --- 2min

4.The second frying: temperature: 160-180°C, time 3min

Technical Data

| Banana Chips Making Line Equipment | 500kg/h(Capacity) | |

| Equipment Name | Power | |

| Plantain Chips Cutting Machine | 1.1KW | |

| Elevator | 0.55KW | |

| Fryer Mamchine | 120KW(henating)+1.5KW(conveying)+0.55KW(lifting) | |

| oil filter | 1.5KW(oil pump) | |

| Vibrating De-oiling Machine | 0.25KW*2 | |

| Drye Machine | 1.1KW(conveying)+0.55KW*6(six fans, each 0.55kw) | |

| Elevator | 0.55KW | |

| Fryer Mamchine | 100KW(heating+1.1KW(conveying)+0.55KW(lifting)+1.5KW(oil pump) | |

| oil filter | 1.5KW(oil pump) | |

| Vibrating De-oiling Machine | 0.25KW*2 | |

| Drye Machine | 1.1KW(conveying)+0.55KW*8(8 fans, each 0.55kw) | |

| Elevator | 0.55KW | |

| Seasoning Machine | 1.5KW |