Features

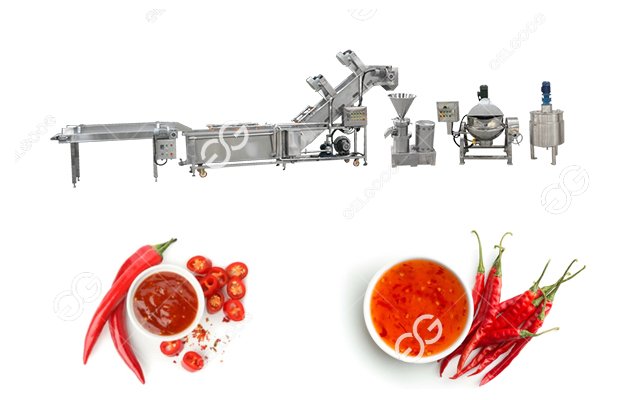

The tomato sauce making production line can realize fully automatic production, mainly including tomato sorting, cleaning, air-drying, crushing, preheating and inactivating enzymes, beating, sterilization, packaging and other processes. The tomato sauce production line processing equipment supporting solutions can be customized according to the output.

introduction of the tomato sauce making machine line

1. Including tomato lifting system, cleaning system, sorting system, crushing system, preheating and inactivating enzyme system, beating system, vacuum concentration system, sterilization system, aseptic big bag filling system.

2. Capacity includes: processing fresh tomatoes 300kg/h, 500kg/h, 600kg/h,1tons/h... etc

3. The final product concentration is: 28-30%, 30-32%, 36-38%

4. There are two ways of manual control or automatic control.

Features of tomato sauce making machine Line

1. Fully automated production:The ketchup production line can be fully automated and can be adjusted according to the production volume and tailor-made solutions.

2. Stainless steel material:Made of 304 stainless steel, it is easy to clean, clean and hygienic, and not easy to rust.

3. High efficiency:The equipment used in the production line can be continuously produced, and has large capacity, high work efficiency, and significantly improved output.

Technical Data

| Description | Technical specifications |

|

Bubble washing and drying machine |

◎Capacity:0.3-0.5t/h; ◎Water recycling system; ◎Elevator:PU Material |

| Crusher machine |

◎Capacity:0.3-0.5t/h; ◎Power: 2.2kw/380v/50hz/3p; ◎Dimension:630*550*1455mm; |

| Heating and concentration/sterilization |

◎Capacity:200liters; ◎Power:1.1kw+18kw/380v/50hz/3p; ◎Pot body size:800*550mm |

|

Sachet packing machine |

◎Model:LY300C; ◎Power:1.8Kw/220v/50hz/1p;; ◎Packing Range: 10-100grams. ◎Packing Speed: 40-80 bags/min |

|

Sterilizer machine |

◎Power:24kw/380V/50Hz/3phase; ◎The bottle will be sterilized in the hot water between 60-80℃. |