Features

Gelgoog Fruit Orange Juice Production Line

This fruit orange juice production line produce several types of fruit juice beverage, orange juice, apple juice, pear juice, grape juice, straw berry juice and so on.Fruit juices are often consumed for their perceived health benefits. And if you want to start the juice business,a good quality fruit juice making machine is very important.Gelgoog fruit orange juice production line with the high production efficiency,easy to clean and repair and low failure rate.Your best choose.

This fruit orange juice production line produce several types of fruit juice beverage, orange juice, apple juice, pear juice, grape juice, straw berry juice and so on.Fruit juices are often consumed for their perceived health benefits. And if you want to start the juice business,a good quality fruit juice making machine is very important.Gelgoog fruit orange juice production line with the high production efficiency,easy to clean and repair and low failure rate.Your best choose.

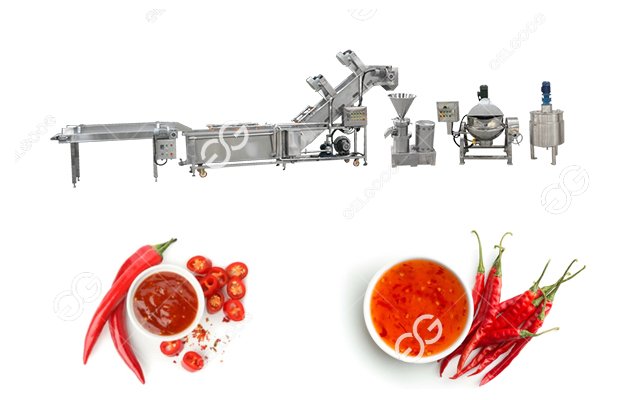

Orange juice line is mainly composed of these machines

Raw materials → brush cleaning machine → roller bar fruit sorting machine → bubble Type washing machine →Juice machine→ low tank → screw pump → preheating enzyme killer → blending tank (2 sets) → vacuum deaerator → Screw pump → tubular sterilization machine → finished product tank → juice pump → three-in-one filling → inverted bottle sterilization → spray cooling → blow-drying machine → cooling machine → automatic labeling machine → automatic film packaging machine

This fruit orange juice production line raw material can be juice concentrate or juice powder, sugar, stabilizer and flavors etc. the procedure method can be blending-UHT sterilizer-homogenizer-hot filling- cooling tunnel- pacakge and so on.And End product package of this can be plastic pouches, plastic cups, plastic bottles, glass bottles, roof top box etc. for this fruit juice production line according to different end product and package type, the production technology is differently designed.

If you only want a fruit juice making machine,we also can offer the fruit juice machine for you

If you only want a fruit juice making machine,we also can offer the fruit juice machine for you

Technical Data

| Machine Name | Machine Size(mm) | Power(Kw) |

| Bubble type washing machine | 2600×1000×1600 | 4.75 |

| Sorting machine | 3500×1000×1200 | 0.75 |

| Brush type cleaning machine | 2500×700×1100 | 0.75 |

| Plate hoist | 3000×900×2000 | 0.75 |

| Hammer crusher | 1050×750×1800 | 4.00 |

| Forced feed pump | 1500×370×420 | 1.50 |

| Spiral fruit juicer | 1580×420×1400 | 4.00 |

| Temporary storage tank | Φ1000×600 | 0.00 |

| Juice pump | 400×300×350 | 0.75 |

| Preheater | 1500×460×1100 | 0.00 |

| Enzymatic hydrolysis tank | Φ1200×1900 | 1.50 |

| Juice pump | 400×300×350 | 0.75 |

| Plate and frame filter | 600×300×500 | 0.00 |

| Temporary storage tank | Φ1000×600 | 0.00 |

| Juice pump | 400×300×350 | 0.75 |

| Diatomaceous earth filter | 950×300×420 | 0.00 |

| Mixing tank | Φ1450×2300 | 2.20 |

| Juice pump | 400×300×350 | 0.75 |

| High pressure homogenizer | 1300×1100×1300 | 22 |

| Juice storage tank | Φ1450×2000 | 0 |

| Vacuum degasser | 1850×1000×2300 | 1.5 |

| Sterilizer machine | 2000×1200×2000 | 5 |

| Fruit juice finished can | Φ1450×2000 |

0 |