Features

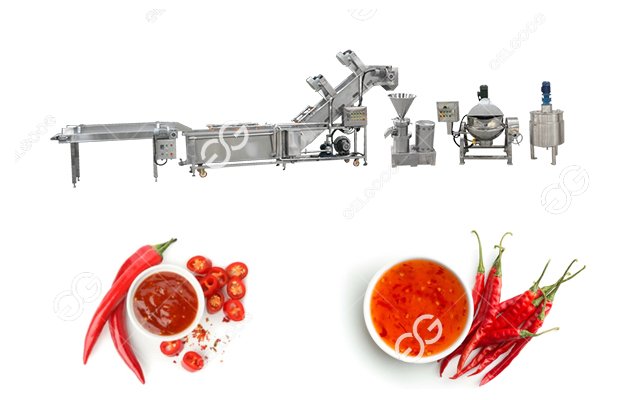

Coriander chutney processing line mainly provides safe and reliable production of various seasoning sauces for small and medium-sized sauce factories. It is mainly composed of material pretreatment (including cleaning, picking), material crushing and refining, sauce preparation and sterilization, and sauce filling. And post-sterilization composition, the entire production line is simple and efficient, the production parameters can be adjusted according to the process of different sauces, and has a high degree of flexibility, whether it is post-adjustment, addition or replacement of process modules is very convenient, and it is easy to It realizes the seamless switching of the production of various sauces. The equipment is simple in composition but can achieve a high degree of automatic continuous production, which can greatly improve the production efficiency compared with traditional production.

Fresh Coriander--washing--crushing--pastemaking--cooking--filling--capping--labeling

①Bubble coriander cleaning machine, using bubble tumbling technology to better clean coriander

②Coriander crushing. Cut the material into small pieces

③Coriander sauce grinder, grind the coriander into a paste

④Heating and concentration: put the juice in the jacketed pot and heat it. In this process, we can add any additives we want: garlic, ginger, sugar, etc. During the concentration process, keep stirring to avoid burning

⑤ coriander paste filling: The produced coriander sauce is filled into the bottle

PS: The processing technology can be customized according to customer needs

Technical Data

|

Coriander chutney Processing line |

Machine Name |

| 1 | Bubble Washing Machine |

| 2 | Sorting Belt |

| 3 | Crushing Machine |

| 4 | Force Feeder Pump |

| 5 | Paste Grinding Machine |

| 6 | Storage Tank |

| 7 | Screw Pump |

| 8 | Mixing Tank |

| 9 | Screw Pump |

| 10 | Bottle Sorting Table |

| 11 | Paste Flling Machine |

| 12 | Capping Machine |