Features

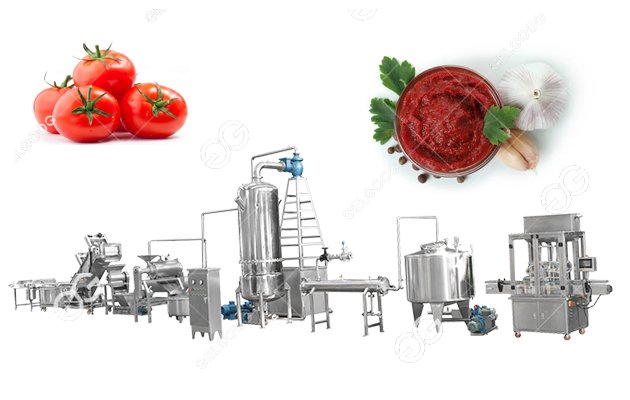

GELGOOG tomato paste production line solution, the main equipment includes tomato washing machine, tomato crusher, tomato beater, filling equipment, sterilization equipment, etc. In order to improve the degree of automation, the equipment will be equipped with elevators, conveyor belts, sorting tables, etc.

Main Machine Of The Tomato Paste Production Line

1. Tomato Washing Machine

Tomato washer uses a bubble type washer to clean the soil and debris on the surface of the tomato by bubbling

2. Tomato Crushing Machine

Broken tomatoes are for better beating and improving pulp yield. Tomato crushing is divided into hot crushing process and cold crushing process.

3. Preheating and deactivation equipment

Tomatoes need to be preheated before beating. The main purpose is to control the activity of pectinase and prevent the separation of juice in the product; to soften the broken pulp, which is beneficial to beating and reduce the loss of beating and increase the viscosity of the product; The air in the interstitial space and juice is conducive to the preservation of vitamins and avoids foaming when heating and concentrating

4. Beating machine

Beating and refining is one of the important processes in tomato paste processing. The crushed tomatoes through the refining machine complete the beating and refining process at one time.

5. Vacuum concentration equipment

It needs to be concentrated nearly six times to make tomato paste. The equipment currently used is still concentrated by vacuum evaporation.

6. Sterilization equipment

Rapid sterilization in a short period of time, so that the nutritional content of the material will not be damaged or lost, and the color of the product will not change;

7. Filling equipment

The filling machine can be customized according to the needs, and can be packaged in various styles according to the design requirements, such as big bag filling, glass bottle filling, etc.

Feature Of The Tomato Paste Processing Machine Line

1. The tomato paste production line (parts in contact with materials) are made of stainless steel, which is easy to clean and hygienic.

2. The output is large and the floor area is small. Through automatic production, the work efficiency is high and the output is significantly improved.

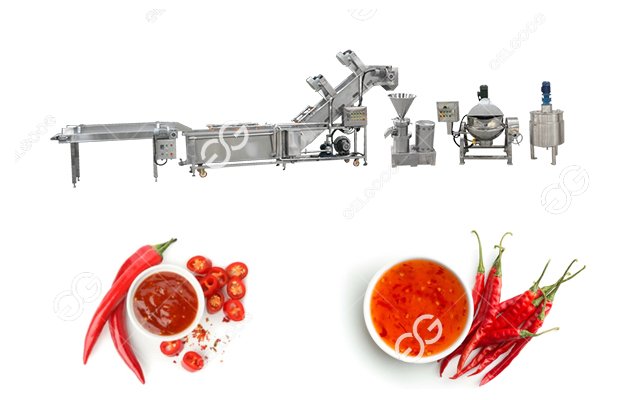

3. It also can meet the needs of cross-season compound production of carrot jam, strawberry jam, chili sauce, blueberry jam and other products.

4. Perfect technological process, coupled with experienced project services, can produce nutritious and delicious tomato sauce with guaranteed quality.

Technical Data

| Tomato Paste Production Line Main Machine | Main Parameters |

| Bubble type tomato washing machne | Powder:4.45KW / 380V / 50Hz |

| Size: 2500x1200x1300mm | |

| Impurity removal machine | Size: 3000 * 1000 * 1400 |

| Power: 5.2KW | |

| Broken screw pump | capacity: 0.5-1 ton / hour; |

| Power: 1.5KW; | |

| Dimensions: 1500 × 500 × 500mm; | |

| Enzyme inactivation equipment | capacity: 1T / H |

| Size: 1220 × 615 × 1250mm | |

| Pulp machine | capacity: 1-2.5 tons / hour |

| Power: 380V, 50Hz, 4Kw; | |

| Temporary storage tank | storage tank: 500L; |

| Exit: φ25.4mm clamp quick-install interface; | |

| Tank body: φ500 × 800 × δ = 2mm; | |

| Discharging height: 200mm, φ25.4mm quick-install interface; | |

| Dimensions: 500 × 1200mm; | |

| Stirring | power: 1.5KW |

| Heating power: 24KW | |

| If the burner is configured: 10W Kcal | |

| Dimensions: 1100 * 980 * 1600 | |

| Body size: 800 * 550 | |

| Filling machine | 1200 * 350 * 350 |

| Voltage 200-250V | |

| Frequency 50 or 60HZ |