Feedback From Customers Of Zambia Tomato Paste Production Line

Dec 02 2021

By Maria

Follow Us:

Dec 02 2021

By Maria

Follow Us:

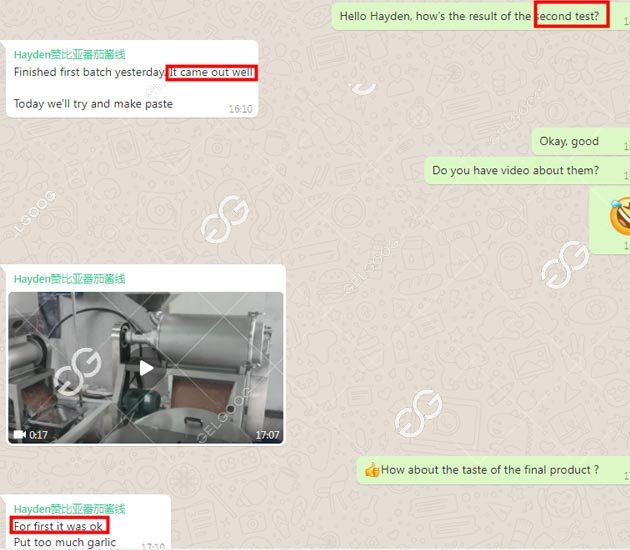

Tomato paste is a hot food in our lives. For tomato growers, processing tomatoes into tomato paste or tomato juice can minimize tomato waste and gain profits.Our Zambian customer is a professional tomato sauce manufacturer. At the beginning, the customer was just a tomato grower and wanted to start this business. However, the specific processing process is not very clear about how to start this business. After a professional understanding ,Only then decided to buy gelgoog equipment for the ketchup business. And the follow-up received feedback from the equipment is very good. If you want to know more about the ketchup business details, you can contact me: maria@mchinehall.com, whatsapp: +8618537181327

How to process tomato paste:

Raw material → washing → crushing → heating and concentration → sterilization → filling → sterilization.

1. Grading of raw materials, choose fully mature fruits with bright color, high dry matter content, thin skin, thick flesh and few seeds as raw materials

2. Washing: wash the silt and dirt on the fruit surface with clean water. Blanching, pour the trimmed tomatoes into boiling water and blanch for 2 to 3 minutes to soften the pulp for beating

3. After beating and blanching, pour the tomatoes into the beating machine to break the pulp to remove the skin seeds and seeds. The beating machine is preferably a double-pass beating machine. The diameter of the first sieve is 1.0 to 1.2 mm.

4. The diameter of the second sieve is 0.8~0.9 mm. After the beating, the pulp juice is heated and concentrated immediately to prevent the pectinase from stratifying.

5. Heating and concentrating, put the juice in the jacketed pot, heating and concentrating, stop heating when the soluble solid content reaches 22%-24%, and keep stirring during the concentrating process to prevent scorching.

6. Sterilize and cool. Sterilize in IOOC boiling water for 20-30 minutes, and then cool until the pot temperature reaches 35-40°C. The sauce body is reddish brown, uniform, and has a certain viscosity, sour taste and no peculiar smell. Soluble solids reach 22% to 24%.

Video About The Tomato Paste Processing Machine Line

Video About The Tomato Paste Processing Machine Line