Considerations For Purchasing French Fries Line

Sep 22 2023

By Maria

Follow Us:

Sep 22 2023

By Maria

Follow Us:

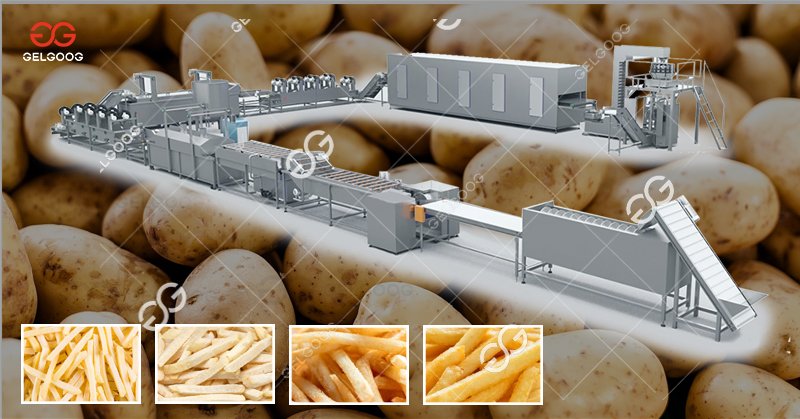

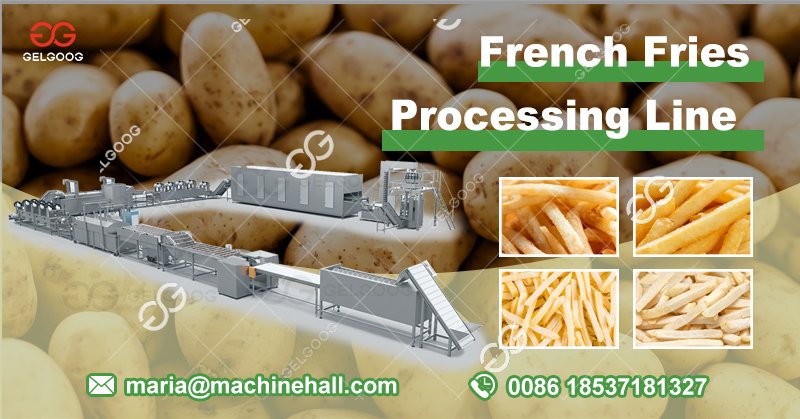

The fully automatic frozen French fries line is an important link can realize the automated production of French fries from cleaning, peeling, slicing, blanching, frying, degreasing, seasoning, packaging and other processes.

Fully automatic French fries line equipment has the following advantages:

- High production efficiency: Fully automatic French fries line equipment can realize full-process automated production, improve production efficiency and reduce labor costs.

- Stable product quality: Fully automatic French fries line equipment can ensure the uniform shape, size, color, taste, etc. of French fries.

- Less environmental pollution: The fully automatic French fries line equipment adopts closed production, which reduces environmental pollution such as oil smoke.

Fully automatic French fries line equipment mainly consists of the following parts:

- washing and peeling machine: used to clean potatoes and remove soil and impurities.

- Slicer: Used to cut potatoes into French fries.

- Blanching machine: Used to remove starch from potatoes to make the fries crispier.

- Frying machine: used to fry French fries.

- Deoiler: Used to remove excess fat from French fries.

- Seasoning machine: used to add seasoning to French fries.

- Packaging machine: used to package French fries.

The selection of fully automatic French fries line equipment needs to be based on the company's production scale, output, product requirements and other factors. For small enterprises, you can choose small fully automatic fries line equipment; for large enterprises, you can choose large fully automatic fries line equipment.

Considerations for purchasing fully automatic French fries line equipment:

- Production efficiency: The higher the production efficiency of fully automatic French fries line equipment, the more conducive it is for companies to increase output and reduce costs.

- Product quality: The fully automatic French fries line equipment should be able to ensure the uniform shape, size, color, taste, etc. of the French fries.

- Environmental pollution: Fully automatic French fries line equipment should adopt closed production to reduce environmental pollution such as oil smoke.

- After-sales service: Choosing a manufacturer with complete after-sales service can ensure the normal operation of the equipment.

- Fully automatic French fries line equipment is an indispensable equipment in the French fries production process. It can help companies improve production efficiency, reduce costs, and ensure product quality.