Features

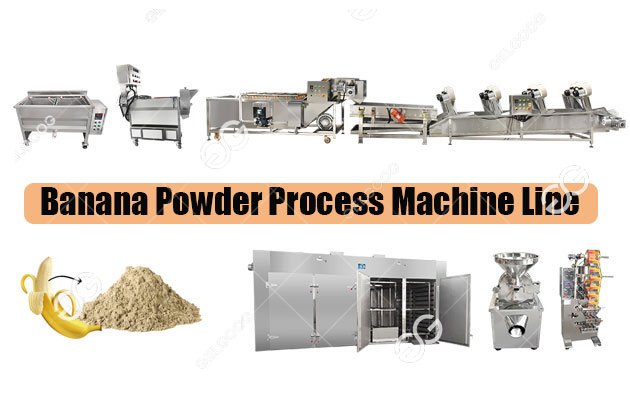

The kava powder production line can also be used for powdering other root products. It is mainly composed of washing machine, drying machine and milling machine. The fully automated production process saves manpower.

The production process of kava powder: cleaning - drying - grinding

Kava cleaning machine: high-pressure bubble water bath cleaning, supplemented by strong water flow, suitable for cleaning stems, leafy vegetables, mushrooms and Chinese herbal medicines, especially for cleaning and desalting wild vegetables and pickled vegetables, with large cleaning capacity , High cleaning rate and no damage to materials

Kava dryer: It is a commonly used continuous drying equipment. Using multi-layer movable stainless steel mesh belt or vibrating plate, the hot air flow passes through the mesh belt and the upper material layer from bottom to top, the heat exchange is uniform and sufficient, the production is stable, and the product quality is good. The material to be dried in the dryer moves along with the conveyor belt, the relative position between the material particles is relatively fixed, and the drying time is basically the same. The dryer is very suitable for drying materials that require consistent color changes or uniform moisture content;

Kava grinding machine: kava powder can be directly discharged from the mill chamber of the main machine, and the particle size can be obtained by replacing the mesh screen with different apertures. This machine is made of stainless steel, there is no dust flying during the production process, and it can improve the recovery rate of materials and reduce the cost of the enterprise. It has the characteristics of firm structure, stable operation and good crushing effect.

Technical Data