Features

Industrial Fruit Chips Drying Oven Machine

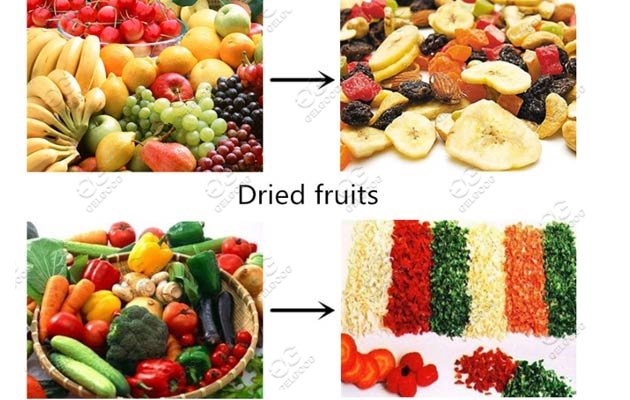

Fruit drying oven machine body is stainless steel, very suitable for food drying.It is widely used for heating and dehumidifying raw materials and products in pharmaceutical, chemical, food, light industry and heavy industry. Especially used for fruit and vegetable food processing. Such as leaf vegetables, cabbage, onions, carrots, apples, lemons, oranges, beans, bananas, pineapples, dates,etc.

Fruit drying oven machine body is stainless steel, very suitable for food drying.It is widely used for heating and dehumidifying raw materials and products in pharmaceutical, chemical, food, light industry and heavy industry. Especially used for fruit and vegetable food processing. Such as leaf vegetables, cabbage, onions, carrots, apples, lemons, oranges, beans, bananas, pineapples, dates,etc.

Advantage Of The Fruit Chips Dryer Machine:

1.High efficiency and low energy consumption.

2.The oven is equipped with an adjustable air distribution plate, which can use forced ventilation to evenly dry the target material.

2.The oven is equipped with an adjustable air distribution plate, which can use forced ventilation to evenly dry the target material.

3.The fruit dryer is in a stable state, has low noise, self-controls temperature, is easy to install and maintain, and runs in a wide range of applications.

4.The heating source is optional, steam or electricity can be used.

5.The hot air circulation drying system can dry food faster.

6.Temperature control, you can set different hot air temperature according to different food.

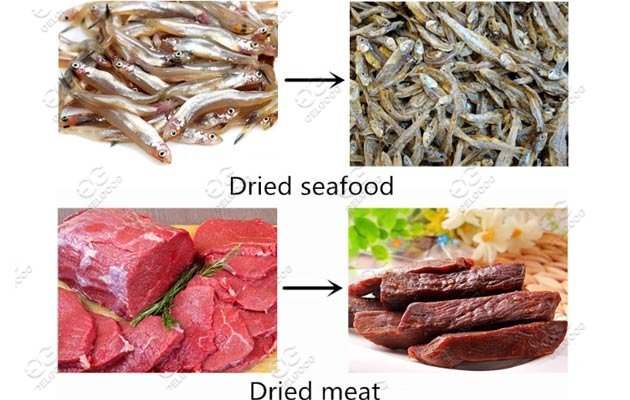

Final Product:

Final Product:

Technical Data

| Model | GGHX-0 | GGHX-1 | GGHX-2 | GGHX-3 | GGHX-4 |

| Number of drying cars | 1 | 2 | 4 | 6 | 8 |

| Baking tray | 24 | 48 | 96 | 144 | 192 |

| Door (fan) | 1 | 2 | 2 | 3 | 4 |

| Circulating fan | 1 | 1 | 2 | 3 | 4 |

| Draining fan (set) | 1 | 1 | 1 | 1 | 2 |

| Heating power (KW) | 12 | 18 | 30 | 48 | 60 |

| Pre-package size (MM) | 1.6x1.2x2.35 | 2.5x1.2x2.35 | 2.5x2.2x2.35 | 3.5x2.2x2.35 | 4.8x2.2x2.35 |

| Weight before packaging (KG) | 470 | 760 | 1000 | 1650 | 2000 |

| Packaged size (MM) | 1.72x1.36x2.26 | 2.63x1.36x2.26 | 2.63x2.26x2.26 | 3.63x2.26x2.26 | 4.93x2.26x2.26 |

| Weight after packaging (KG) | 520 | 830 | 1100 | 1800 | 2150 |

| Production (KG) | 72 | 144 | 288 | 432 |

576 |