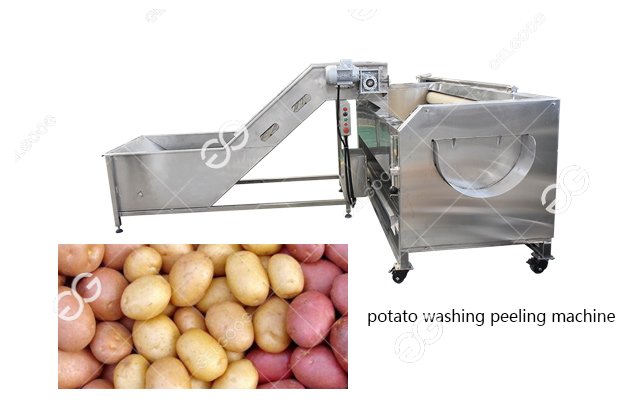

Introduce Of The Brush Roller Type Potato Washing Peeling Machine

Aug 16 2021

By Maria

Follow Us:

Aug 16 2021

By Maria

Follow Us:

Equipment structure principle: The potato washing peeling machine is arranged in a straight line by multiple hair rollers. When the hair roller is driven by the motor synchronously, it rotates along the direction of the discharge port; using the friction force of the hair roller on the hair roller and the centripetal force of itself, The material moves along the position of the inlet to the position of the outlet; the brush contacts the surface of the material during the movement to remove the hair and other impurities on the surface of the material; under the action of the circulating pump, the water enters the nozzle along the spray pipe , The material itself is washed; washing the material with medium water can reduce the friction between the material itself and the brush to prevent damage, and at the same time flush away the impurities washed out of the surface of the material in time.

Features Of The Potato Washing Peeling Machine :

The use of food-grade stainless steel is safe and reliable, pollution-free, stable in conveying, quick-freezing adjustable, fruits and vegetables move with the conveyor belt, which can avoid damage to fruits and vegetables, with low noise, and suitable for places where the working environment requires relatively quiet. The structure is simple, easy to maintain, and low energy consumption. Low cost of use.

This machine is made of SUS 304 material. While cleaning, a spray pipe nozzle is added to the upper part of the mesh belt, and the high-pressure water pump is used for circulating spray, which effectively suppresses the material floating and material cleaning. The nozzle is a detachable nozzle, which is easy to clean and prevent clogging. Adjustable angle, more effective cleaning of fruits and vegetables.

1. All stainless steel material, the whole equipment is made of SUS304 stainless steel, beautiful and durable, and meets national sanitary requirements.

2. Nylon hair rollers: Nylon hair rollers are used (the number of hair rollers can be determined according to the length of the machine). The roller brush material is treated with a special process (rolled with nylon cord), which is durable and has good wear resistance. The brush roller of the equipment adopts nylon brush wire and precision brush, which is wear-resistant and does not fall down. It can be cleaned and has a luster.

3. Chain transmission The conveyor belt motor can realize the function of frequency conversion and speed regulation. The cleaned material is conveyed through the chain, and the material is automatically fed and discharged, which saves labor.

4 Circulating water pump:The filtered water circulating water pump can realize water recycling and save water more. It can be replaced with new water according to the actual situation. Filter the water tank, the water tank is added with a filter, the dirt in the cleaning will be filtered out to achieve the cleanliness of the water.

5. The surface of the material is brushed with nylon silk wool roller to complete the cleaning, polishing and peeling treatment.

6. The sprinkler system is equipped with a spray device on the top of the sprinkler water spray system, which has a good cleaning or peeling effect.

7. Special discharge port design, fast discharge speed, no damage to materials.

8. It is driven by a built-in two-stage drive device, which is reliable in operation.

9. It is suitable for washing, polishing and peeling round and oval fruits and vegetables. In the hair stick peeling cleaning machine, the material is rotated by the brush, and the surface of the material is rubbed with the brush, so as to achieve the effect of cleaning, peeling and polishing the material. The thickness of the brush should be selected for cleaning, peeling and polishing. It adopts centrifugal rotation, touch sassafras peeling technology. The machine is exquisite in structure and easy to operate. It is suitable for washing and peeling potatoes in restaurants and canteens.

10. The equipment is equipped with four universal wheels at four points, making it easy to move.

11. Equipped with a six-stage motor, the strength is large, which can make the material fully friction with the brush, and increase the friction force. At the same time, the work adopts the technology of tumbling, soft brushing and high-pressure water spraying to carry out the article to the limit. Clean. 12. The cleaning operation speed is steplessly adjustable, and the user can set arbitrarily according to different cleaning contents.